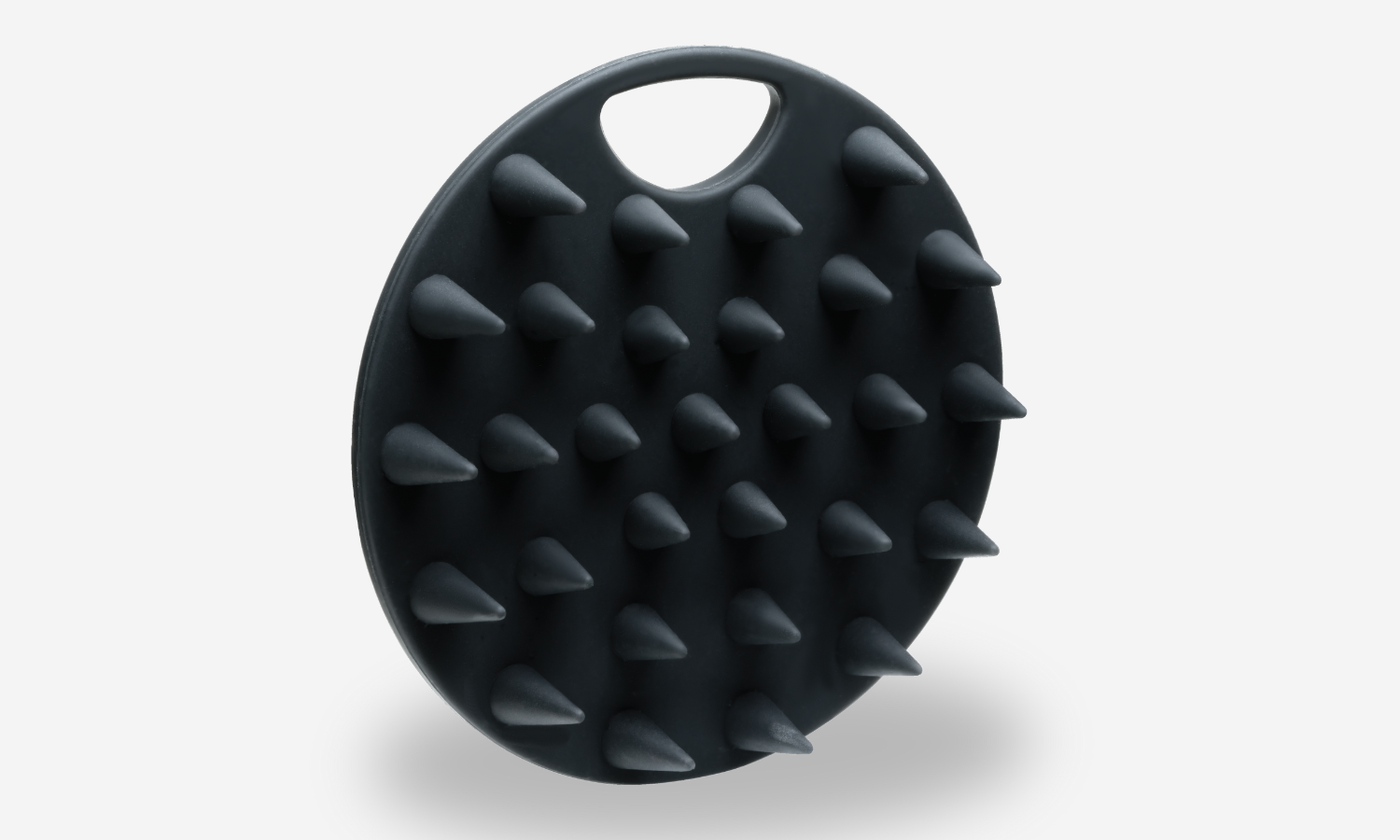

Behind the Scenes: The Making of flexii Silicone Scrubbers.

At flexii, we pride ourselves on delivering high-quality, eco-friendly silicone scrubbers that transform your skincare routine. Our commitment to excellence extends from the design phase to production, ensuring each product meets our rigorous standards for performance and sustainability. Here’s a behind-the-scenes look at how flexii silicone scrubbers are designed in UK and made in our state-of-the-art facilities in China.

1. Design and Innovation

Every flexii silicone scrubber starts with a vision for superior skincare. Our design team in London collaborates with engineers and material scientists to create innovative scrubbers that address common skin issues effectively. The process involves:

- Research and Development: Extensive research on skin types, common skincare problems, and user preferences guides the development of our scrubbers. This research ensures that our products are both effective and user-friendly.

- Prototyping: Initial designs are transformed into prototypes using advanced 3D printing technology. These prototypes are tested for comfort, durability, and performance, with adjustments made based on feedback.

2. Material Selection

The quality of our silicone scrubbers begins with the raw materials. We use medical-grade, hypoallergenic silicone that is safe for all skin types. This silicone is:

- Non-Toxic: Free from harmful chemicals and additives, ensuring that it is gentle on your skin.

- Durable: Designed to withstand repeated use and maintain its effectiveness over time.

- Eco-Friendly: Silicone is derived from silica, a plentiful and sustainable resource. Its durability means less frequent replacements, contributing to waste reduction.

3. Manufacturing Process

Our manufacturing facility in China adheres to strict quality control standards to produce flexii silicone scrubbers. The manufacturing process involves several key steps:

- Molding: Liquid silicone is injected into precision molds to form the shape of the scrubbers. The molds are designed to create flexible, soft bristles that provide gentle exfoliation.

- Curing: The molded silicone is then cured in a controlled environment to ensure it sets properly. This step is crucial for achieving the desired texture and durability.

- Trimming and Inspection: Once cured, each scrubber is trimmed to remove any excess material and inspected for defects. Our quality control team checks for uniformity in bristle length, overall shape, and any potential flaws.

4. Quality Assurance

Maintaining high quality is a cornerstone of flexii’s manufacturing process. Our quality assurance measures include:

- Rigorous Testing: Each batch of scrubbers undergoes a series of tests to ensure they meet our standards for strength, flexibility, and safety. This includes stress tests, chemical resistance tests, and user trials.

- Certifications: Our manufacturing facility is ISO-certified, reflecting our commitment to maintaining international standards for quality management and environmental responsibility.

5. Sustainability Practices

flexii is dedicated to minimizing our environmental impact throughout the production process. Our sustainability practices include:

- Efficient Manufacturing: We use energy-efficient machinery and processes to reduce our carbon footprint.

- Waste Management: Excess silicone from the molding process is recycled and reused, minimizing waste.

- Eco-Friendly Packaging: Our packaging is designed to be minimal and recyclable, reducing the environmental impact.

6. Partnerships and Distribution

After production, flexii silicone scrubbers are carefully packaged and prepared for distribution. We partner with logistics providers who share our commitment to sustainability, ensuring that our products reach you efficiently and with minimal environmental impact.

The making of flexii silicone scrubbers is a testament to our commitment to quality, innovation, and sustainability. From design to delivery, each step is meticulously managed to ensure that you receive a product that enhances your skincare routine while being kind to the environment. Our state-of-the-art manufacturing facility in China operates under stringent quality control standards, ensuring that every flexii scrubber meets our high standards. By choosing flexii, you’re not only investing in better skincare but also supporting eco-friendly practices and sustainable manufacturing.